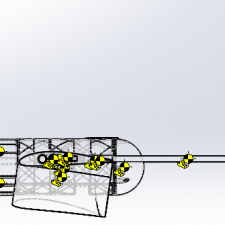

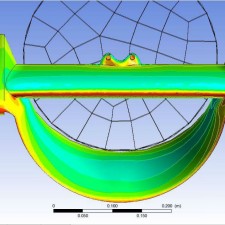

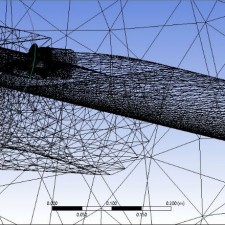

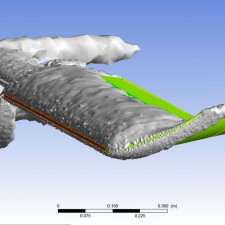

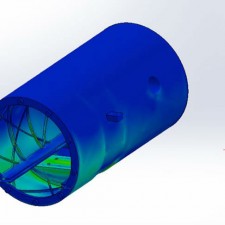

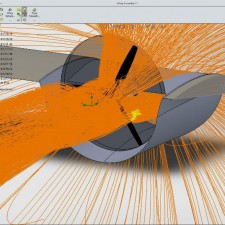

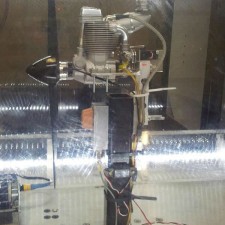

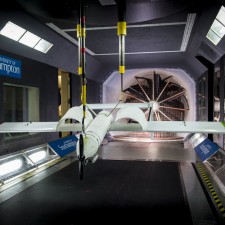

The overall aim of this project was to develop a UAV effective for operation from a Royal Navy vessel. A UAV with the required capability was designed, optimised and manufactured using mostly 3D printing. Initial performance estimates were close to being achieved through the successful employment of Custer ducts to reach a theoretical flight speed of 9m/s and proven speed of 11 m/s (approximately 20 mph and 24 mph respectively). The use of Custer ducts provides a significant increase in lift at low speeds through a complex aerodynamic interaction between the air flow, the duct and the propeller. This successful design was achieved through an iterative development process where designs were analysed with computational flow dynamics and optimised based on the simulation results. This led to the augmented lift from the ducts totalling 71.4% of the total lift at the lowest speed based upon wind tunnel testing. The large tail and control surfaces, as well as a correctly-balanced airframe, provide the pilot with good control authority at lower speeds.

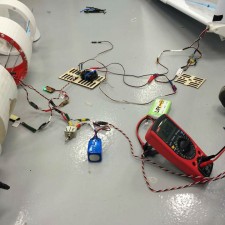

The initial target mass of 12 kg was exceeded with an actual all up mass is 13.2 kg; despite attempts to reduce weight through design optimisation and careful component selection. This value stems from a large amount of circuitry required to control the aircraft, a fuel tank for the wet fuel engine and the structure to support the 3 metre wingspan. In the current configuration, a flight time of 45 minutes is theoretically possible.

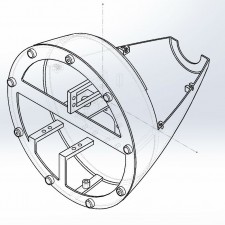

The use of 3D printing to produce a modular fuselage provided several advantages. The level of geometric complexity would not have been possible to produce using conventional manufacturing methods. Additionally the use of a modular fuselage gave much better adaptability for the overall design. This resulted in the successful balancing of the aircraft and gives scope for greater utility in the future. Notably, this provides evidence that UAVs could be manufactured on board maritime platforms. This would allow for task specific modules to be incorporated into the design quickly and without the need for supply network.

The result of this work is a functional aircraft with a wider range of capabilities than previous Custer UAVs produced by the universities. Though the specific objectives of the project were not fully realised; a highly capable aircraft was produced which could be developed into a prototype for deployment on a naval platform.

The initial target mass of 12 kg was exceeded with an actual all up mass is 13.2 kg; despite attempts to reduce weight through design optimisation and careful component selection. This value stems from a large amount of circuitry required to control the aircraft, a fuel tank for the wet fuel engine and the structure to support the 3 metre wingspan. In the current configuration, a flight time of 45 minutes is theoretically possible.

The use of 3D printing to produce a modular fuselage provided several advantages. The level of geometric complexity would not have been possible to produce using conventional manufacturing methods. Additionally the use of a modular fuselage gave much better adaptability for the overall design. This resulted in the successful balancing of the aircraft and gives scope for greater utility in the future. Notably, this provides evidence that UAVs could be manufactured on board maritime platforms. This would allow for task specific modules to be incorporated into the design quickly and without the need for supply network.

The result of this work is a functional aircraft with a wider range of capabilities than previous Custer UAVs produced by the universities. Though the specific objectives of the project were not fully realised; a highly capable aircraft was produced which could be developed into a prototype for deployment on a naval platform.