The America’s Cup has inspired a generation of hydrofoiling sailing vessels capable of reaching speeds of up to 50 knots, leading to many young sailors moving into foiling dinghies. Up to this point hydrofoiling has been viewed as an expensive and inaccessible technology only for the elite.

Currently, research into this area is performed by both industry and academics using computational methods and model testing, both incurring significant cost. This project aimed to produce a test platform to allow on the water research to be completed into the design and operation of hydro-foiling technology while also providing a foiling platform that anyone can use. The platform was based on an existing Nacra F18 catamaran which was then adapted using a series of systems to allow hydrofoiling to take place.

This project was split into three design and build sub-areas; the hydrofoils and rudders, an attachment system and an electronic system to record and process structural and performance data. The hydrofoils, designed to lift the 350 kg platform at 10 knots, were manufactured from prepreg carbon fibre by the team onsite at the University. The attachment system (pods) allowed a variety of different foils with different section shapes to be housed and adjusted. These pods also have the unique advantage of being able to be fitted to any small catamaran, making hydrofoiling technology more widely available. With the foils and platform fully instrumented sailing data can be gathered for future design improvements.

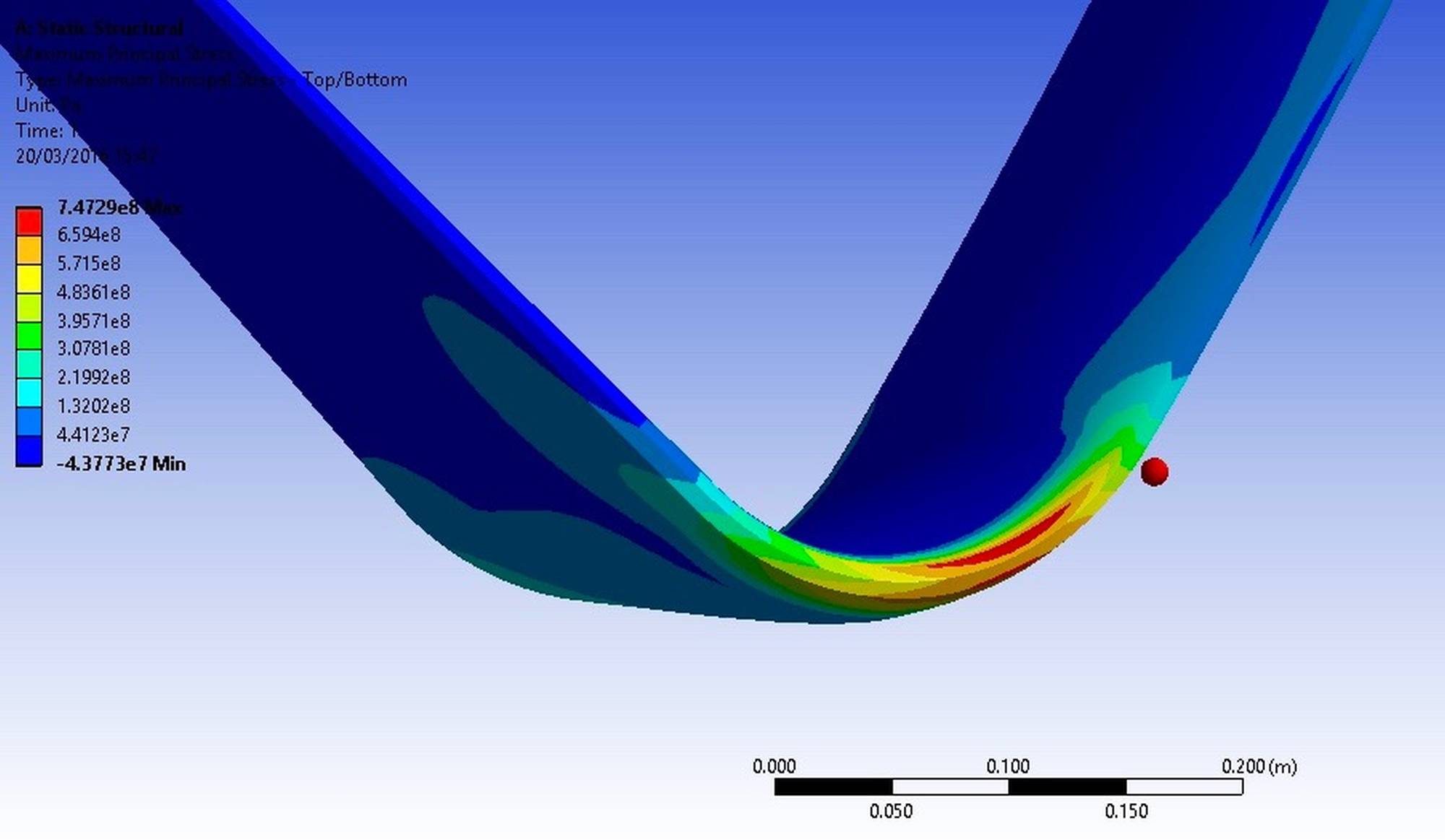

This process involved computer based testing within the design process, including computational fluid dynamics and finite element analysis, as well as hand based calculations and research into existing vessels.

The platform was tested in its assembled state in March 2016 on Southampton Water where two tow tests were undertaken. These tests proved successful with the vessel repeatedly foiling when travelling at 10 knots.

Currently, research into this area is performed by both industry and academics using computational methods and model testing, both incurring significant cost. This project aimed to produce a test platform to allow on the water research to be completed into the design and operation of hydro-foiling technology while also providing a foiling platform that anyone can use. The platform was based on an existing Nacra F18 catamaran which was then adapted using a series of systems to allow hydrofoiling to take place.

This project was split into three design and build sub-areas; the hydrofoils and rudders, an attachment system and an electronic system to record and process structural and performance data. The hydrofoils, designed to lift the 350 kg platform at 10 knots, were manufactured from prepreg carbon fibre by the team onsite at the University. The attachment system (pods) allowed a variety of different foils with different section shapes to be housed and adjusted. These pods also have the unique advantage of being able to be fitted to any small catamaran, making hydrofoiling technology more widely available. With the foils and platform fully instrumented sailing data can be gathered for future design improvements.

This process involved computer based testing within the design process, including computational fluid dynamics and finite element analysis, as well as hand based calculations and research into existing vessels.

The platform was tested in its assembled state in March 2016 on Southampton Water where two tow tests were undertaken. These tests proved successful with the vessel repeatedly foiling when travelling at 10 knots.

- The starboard rudder during the second tow test

- The platform fully foiling during the second tow test

- Adjusting the pitch of the hydrofoils using the pod control system

- Finite Element Analysis of the main hydrofoils to determine maximum stresses

- Model of the designed hydrofoils and pod attachment system attached to an A Class Catamaran (https://grabcad.com/library/class-a-catamaran-1)